How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems

How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems

Blog Article

Recognizing the Capability of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser acts as an essential instrument in modern production, offering specific, non-contact measurements that are important for preserving strict sector criteria. By leveraging innovative laser technology, these analysers not just make sure very little signal loss yet also enhance the general performance of optical fibres. Moreover, their capability for real-time data handling allows manufacturers to promptly address any type of inconsistencies from specs, promoting a culture of continual improvement. Recognizing the ins and outs of this modern technology questions about its broader ramifications in manufacturing performance and quality control across numerous sectors.

Significance of Optical Fibre Dimension

In modern-day production, the measurement of optical Fibre Diameter is crucial for making sure the efficiency and dependability of Fibre optic systems. Exact Diameter measurement straight affects optical efficiency, as variations can lead to boosted signal loss, lowered bandwidth, and lessened general efficiency. The optical residential properties, including light transmission and signal integrity, are extremely delicate to the Fibre's Diameter, requiring specific control throughout production.

Moreover, standardization in Fibre Diameter is vital for compatibility and interoperability within diverse telecoms networks. As these networks increase around the world, maintaining uniformity in Fibre characteristics advertises seamless assimilation throughout different elements and systems. In addition, sticking to industry requirements concerning Diameter tolerances is essential for suppliers to fulfill regulatory demands and customer expectations.

Spending in innovative dimension technologies not only improves manufacturing performance however additionally supports quality control processes, making it possible for producers to determine problems early in manufacturing. This proactive technique minimizes waste and makes sure that the final products meet rigid efficiency requirements. Subsequently, the importance of optical Fibre dimension can not be overstated, as it works as a foundation for premium, trusted Fibre optic systems, which are indispensable to modern interaction infrastructure.

Exactly How Diameter Analysers Job

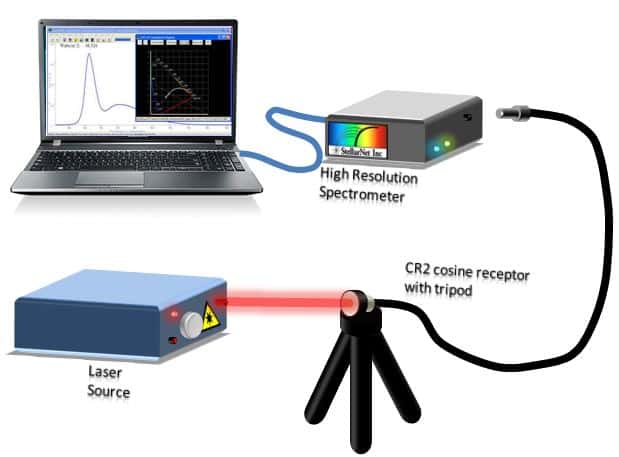

The core procedure counts on the principle of light spreading and reflection. As the laser beam of light strikes the Fibre, variations in Diameter cause changes in the light's strength and wavelength (optical fibre diameter analyser). This data is processed in real-time using innovative algorithms that equate the optical signals into precise Diameter dimensions

Furthermore, numerous Diameter analysers are equipped with multiple dimension points along the Fibre, enabling a thorough evaluation of Diameter uniformity. This is critical in guaranteeing that the optical fibres fulfill strict industry criteria. The whole process is automated, allowing high-speed measurements and lowering human mistake. The application of such modern technology considerably boosts quality assurance in production, ensuring that optical fibers are created to exact requirements for optimal performance in their desired applications.

Secret Features to Consider

When picking an optical Fibre Diameter analyser, a number of key features require cautious consideration to make certain optimum efficiency and reliability. First, measurement precision is critical; the analyser needs to supply exact Diameter readings, normally in micrometers, to meet rigid production specs. Additionally, a wide dimension variety improves versatility, suiting various Fibre types and densities.

An additional important feature is the analyser's rate. Fast measurement capacities enable increased throughput, crucial in high-volume production settings. Additionally, real-time information handling and feedback abilities allow immediate adjustments, improving quality control.

User user interface and software compatibility are additionally considerable factors to consider. A straightforward interface enhances procedure, while robust software program assistance helps with information evaluation and assimilation with existing manufacturing systems. The ability to export information in different styles can improve coverage and conformity initiatives.

Additionally, sturdiness and maintenance demands need to be reviewed. An analyser created from high-quality materials will certainly stand up to the rigours additional resources of a production environment, while ease of maintenance guarantees long life and reduces downtime. Last but not least, take into consideration the degree of technological assistance and training provided by the manufacturer, as this can considerably impact the efficient use the analyser in manufacturing settings.

Advantages in Production Effectiveness

Enhancing manufacturing effectiveness depends upon the assimilation of advanced innovations, such as optical Fibre Diameter analysers. These tools play an essential function in making certain that optical fibres satisfy rigorous quality standards, which is crucial for optimum performance in numerous applications - optical fibre diameter analyser. By supplying real-time dimensions of Fibre Diameter, suppliers can quickly recognize and remedy deviations from specified tolerances, thereby lowering waste and minimizing the risk of defective products

Additionally, the very early discovery of prospective issues results in lowered downtime and upkeep prices, consequently enhancing resource appropriation. Inevitably, the effectiveness gets recognized with the use of optical Fibre Diameter analysers add to a more competitive production setting, guaranteeing that business can supply top notch items while preserving cost-effectiveness and responsiveness to market needs.

Applications Throughout Industries

The adaptability of optical Fibre Diameter analysers expands past making performance, locating applications across different markets that depend on optical Fibre innovation. In telecommunications, these analysers are vital for making certain the optimal performance of Fibre optic wires, straight impacting data transmission prices and network integrity. By precisely determining Fibre sizes, operators can lessen signal loss and improve overall interaction high quality.

The clinical industry also profits considerably from these tools, especially in the advancement of endoscopic devices and laser treatments. Exact Diameter dimensions are important for creating effective optical fibers that are utilized in minimally intrusive procedures, improving individual outcomes through boosted imaging and treatment capabilities.

In aerospace, the analysers play a critical function in the production of lightweight, high-strength materials, where Fibre optics are incorporated right into structural elements for monitoring and diagnostics. In addition, the automobile try this website market utilizes these tools to ensure the integrity of Fibre optic sensing units that boost security and efficiency features in lorries.

Conclusion

In final thought, the optical Fibre Diameter analyser is essential for modern manufacturing, making sure exact dimensions that support sector requirements. The varied applications across numerous markets highlight the analyser's significance in promoting continual improvement and data-driven decision-making within the production sector.

In modern manufacturing, the measurement of optical Fibre Diameter is critical for guaranteeing the performance and reliability of Fibre optic systems. The significance of optical Fibre dimension can not be overstated, as it offers as a structure for high-quality, reliable Fibre optic systems, which are important to modern-day communication facilities.

Diameter analysers use innovative optical technologies to properly gauge the Diameter of optical fibres.In addition, many Diameter analysers are outfitted with multiple measurement points along the Fibre, permitting for a comprehensive evaluation of Diameter uniformity.The versatility of optical Fibre Diameter analysers extends beyond making effectiveness, locating applications throughout different sectors that rely on optical Fibre innovation.

Report this page